When you flush the toilet or turn on the faucet in your home, at work, or in a restaurant, chances are you don’t think about the path wastewater takes to be treated or the systems required behind the scenes to do so. For the Public Wastewater Team at Foth, we’re thinking about how these systems work and how to make them work better all the time.

Municipalities across the U.S. and the world are tasked with planning for and responding to population growth and the increased handling of wastewater it brings, as well as the continuing requirement to treat wastewater to higher standards. When designing wastewater conveyance systems to accommodate new housing developments and increased populations, there is significant pressure to plan well for the future.

Foth’s Approach to Public Wastewater Projects

At Foth, one of our primary considerations in supporting municipalities with their wastewater conveyance projects is to plan for the future, considering expandability and maintenance requirements for the next several decades. Because municipal wastewater conveyance projects take years to plan and implement, it is imperative our clients don’t have to return to the drawing board five years later due to an unanticipated circumstance.

In any infrastructure project – public or private – budget constraints are a key consideration. Staying within budget means ensuring timelines are met and few, if any, issues requiring rework add to the schedule. On this front, Foth has developed systems, tools, and processes that allow for high levels of accuracy, efficient collaboration, and ultimately, successful projects that achieve desired outcomes.

Using 3D Technology to Better Deliver Wastewater Projects

Over the last several years, our processes and project deliverables have changed immensely. Without the technology offered today, we relied solely on manual processes and hard copy drawings. To show a client various views and angles of an engineering design, we were required to draw each manually, which was not only a time-intensive process, but lacked the ability to show the level of detail we are able to show today.

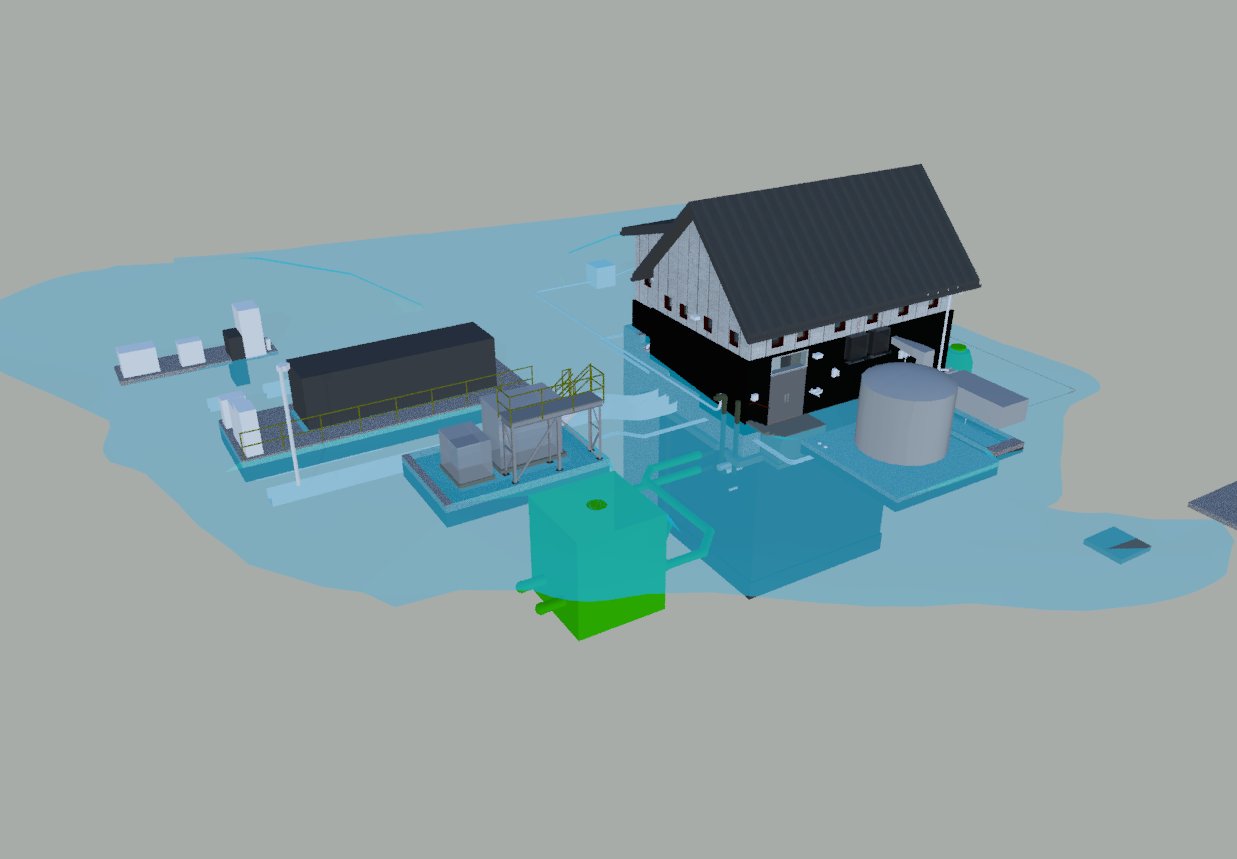

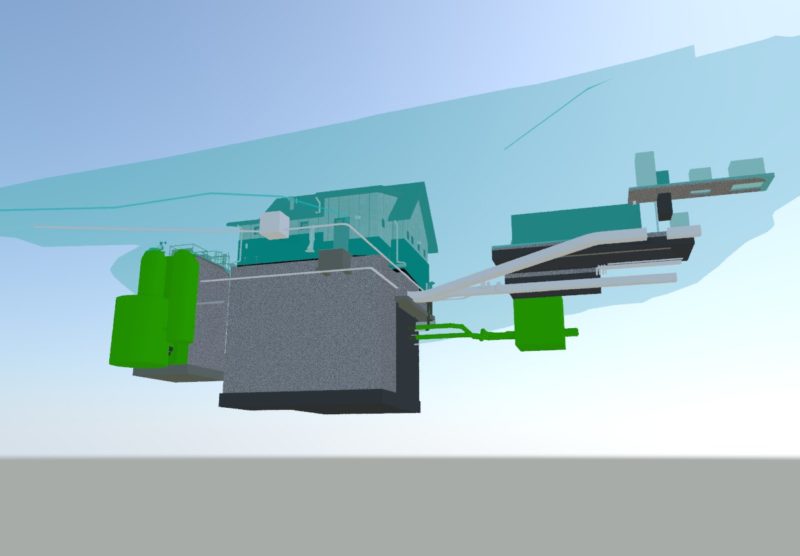

Today we use such tools as Revit for 3D modeling the design components on the interior and exterior of a wastewater treatment facility or pump station. We also use Revit to further attribute the 3D model to include details such as bid items and specifications, thus creating a BIM model. From there, we can publish to tools like Navisworks to review the design with clients, operators, and contractors.

Using 3D modeling allows us to show all those involved how the building and system will look and feel, including minute levels of detail such as the amount of headspace included in sections of the building. 3D technology allows us to incorporate the design of the electrical, mechanical, and civil features in one federated BIM model, providing an enhanced client review and approval process.

Changing the Client Experience

During the design and review process, clients can interact with the model, request changes, and see the effects of such changes in real-time. This ability to perfect the design leads to significant decreases in changes during construction, which are more difficult, cost-intensive, and present more limitations.

Clients have more choice in how they review the design of their facility. Virtual Reality – or VR – headsets allow clients to immerse themselves into the design at a 1:1 scale to see how each component will work and interact with one another as well as note areas of concern and changes using digital markup tools. Clients can ‘walk through’ their new facility using VR technology to experience their project and ensure everything is just right before delivering approval for construction. Where engineering drawings are more difficult to decipher, VR makes it simple for those from non-engineering backgrounds to review a design and provide feedback.

Using 3D models helps in communicating with contractors who will be part of the construction team and increases the clarity contractors have in terms of scope and deliverables. Often clients can reduce their contingency budgets due to the high degree of certainty provided by Foth’s approach.

Using the Latest Technology for Your Next Wastewater Facility Project

At Foth, we work on wastewater projects of varying complexity. Whether your project involves modifications to an existing pump station, a new lift station, or creating end-to-end wastewater treatment systems to accommodate a new housing development, our decades of experience ensures we ask the right questions and anticipate not only the challenges we’ll face today, but 20 years down the road. We bring our technical expertise and creativity to ensure your project is successful from both a bottom-line and community perception perspective.

Get in touch with us today to find out how we will put our leading-edge approach to work on your next wastewater project.

By Ted Schultz, PE, Senior Client Manager

Markets: Municipalities, Utilities

Services: Strategic Consulting and Planning, Water and Wastewater