Background

In 2020, Foth completed a partnership with Xcel Energy that converted a once-contaminated waterfront eyesore into a pristine public amenity for the community of Ashland, Wisconsin. Along the way, they employed a methodology critics said “couldn’t be done.” In the end, they surpassed the Environmental Protection Agency’s (EPA) standards for soil and sediment clean-up, met stringent water quality standards for the pristine Lake Superior environment and earned the trust and respect of the residents of Ashland.

Restoring One of the World’s Most Pristine Fresh Water Sources

Spanning Canada and the United States, Lake Superior’s more than 30,000 square miles of fresh water make it the largest Great Lake in North America, and a prized resource for inhabitants from shore to shore. While Lake Superior is recognized as one of the world’s most pristine sources of fresh water, it has a history of its lakefront being used for industrial purposes in multiple locations dating back over a century, including in Ashland, Wisconsin.

The results of industrial activity on the shore of Chequamegon Bay in Ashland led to its designation as a Superfund Site by the EPA in 2002. What followed was a decade-long remediation project that included cleaning up approximately 40 acres of heavily contaminated soil and sediment on land and in the bay. The magnitude of complexities associated with the project was novel for all involved – it took consulting with thousands of residents and interested stakeholders, meeting rigorous agency standards, coordinating more than 40 contractors, and completing the work during a limited April to October annual construction schedule.

In 2019, the EPA gave its stamp of approval on the cleanup after its first five-year review. The in-bay portion exceeded its cleanup target of a Surface Weighted Average Concentration (SWAC) of 9.5 Parts Per Million (PPM) total polynuclear aromatic hydrocarbons (tPAH), coming in at just 2.38 PPM. The lakefront is restored for the community to enjoy fishing, boating, and swimming, and what was once a contaminated eyesore is now a pristine panoramic view of a clear, clean Lake Superior.

History of the Ashland, Wisconsin Site

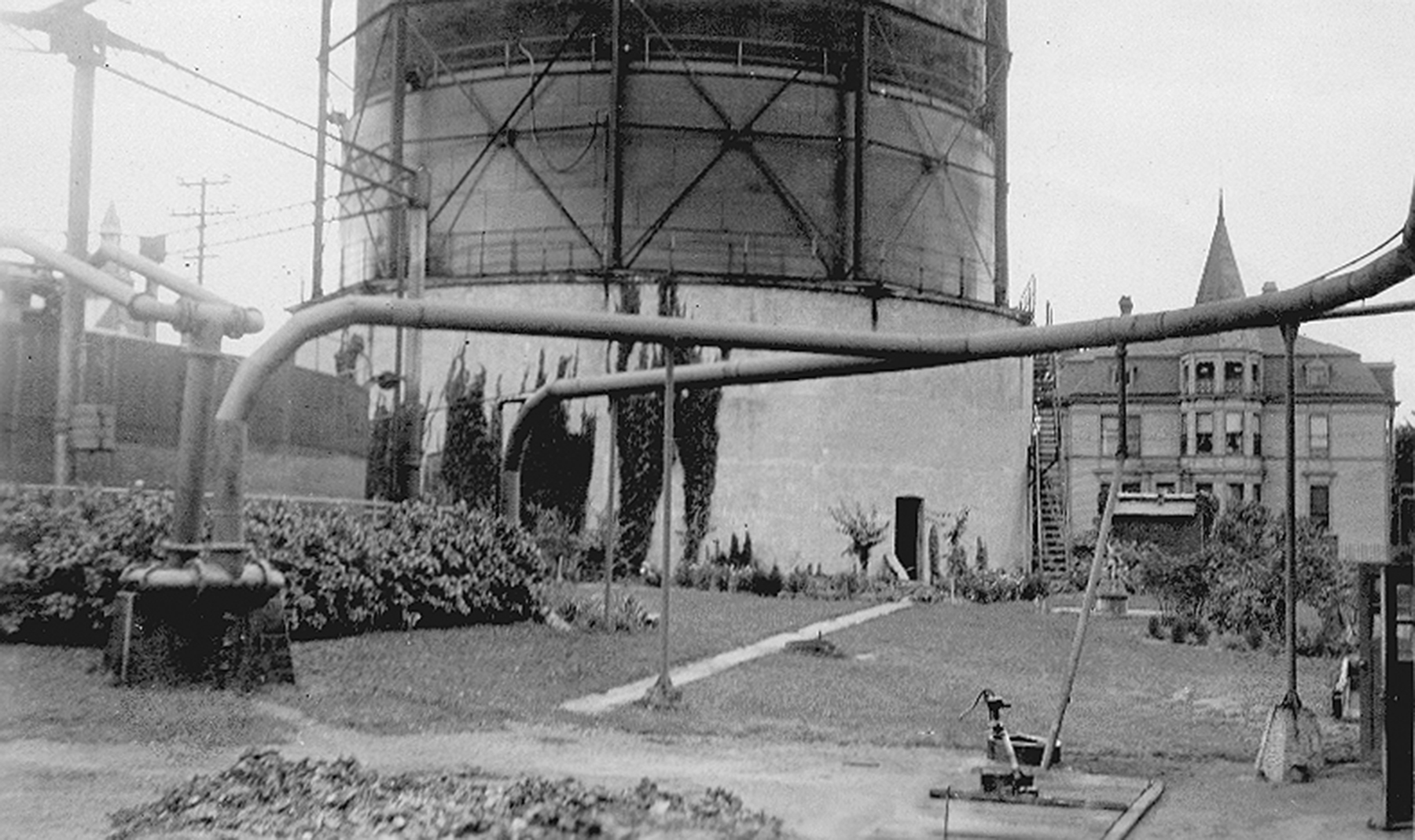

In the early 1900s, the Ashland lakefront was part of a highly industrialized site, and several companies and activities contributed to the contamination including utilities, sawmills, and a landfill. While most companies were gone come the latter part of the 20th century, their legacy remained, including that of the manufactured gas plant (MGP), owned by what was then Northern States Power Co.

The MGP, which operated from 1845 to 1947, was determined to be the main source of contamination in 1995 following the Wisconsin state-funded investigation. MGPs were staples across the United States in the late 1800s to the mid-1950s before natural gas was made widely available via pipelines. To provide heat, lighting, and gas for cooking, MGPs manufactured gas from fuels such as coal and oil, creating unwanted waste – typically coal tar – which would be discharged into nearby waterbodies or leak into surface and subsurface soils, and ground water.

The City of Ashland was seeking to expand its lakefront wastewater treatment plant in the 1980s when the contamination was discovered. After the appropriate agencies, including the EPA and the Wisconsin Department of Natural Resources (WDNR), became involved and investigated likely sources, Xcel Energy, formerly Northern States Power Co., took the lead in the cleanup in 1999 as the project proponent.

In 2009, Foth was brought on as the prime contractor in a joint venture with Envirocon. In its largest design-build project to date, in which Foth oversaw the remediation from start to finish, 82 Foth members brought their experience, innovation, and passion to the cleanup which concluded in 2020.

Building Relationships and Trust Early On

Several factors made the cleanup unique – the first being its price tag. Multimillion-dollar remediation projects are not cookie cutter, especially those in the middle of a city. The project site was surrounded by a marina, residences, a city RV park, the Hotel Chequamegon, and Our Lady of the Lake Catholic Church and School, which made up just a few of the interested stakeholders. The others included the close to 8,000 residents of Ashland who used the lakefront regularly and had a vested interest in the efficiency and efficacy of the remediation.

Understanding the uniqueness of the project, the area, and the stakeholders, the project proponent along with is contractors, including Foth, set about to create a meaningful consultation plan.

“A core tenet of the remediation project was to plan it in conjunction with the community,” said Denis Roznowski, Project Director at Foth. “Instead of creating and presenting a plan on which the community could comment, we started by asking questions and listening to stakeholders to understand concerns, priorities, and values.”

From these conversations, and regular meetings with the Community Advisory Group, which acted as a continuous feedback loop between the community and the project team, the team understood concerns existed related to access to local businesses, dust, odor, air quality (and perception of air quality), impacts to boaters, and more. To respond to these concerns, the team put in place several mechanisms through which stakeholders could ask questions and receive immediate responses, including a hotline on site and a website displaying current air quality monitoring results, as well as a comparison of those results to applicable standards.

“The key to successfully completing this project was building trust – between the agencies (including the EPA and WDNR) and the project team, and between the project team and the community,” said Roznowski. “Over several years, Xcel Energy and its contractors developed a cycle of trust by informing stakeholders about what would be occurring, before it happened, executing the task according to the information given, and then following up to inform stakeholders of the results. This led to more efficient decision-making, better collaboration between impacted parties, and ultimately a better remediation.”

Xcel Energy and its contractors created an innovative legal framework called an Adaptive Management Approach to facilitate field-level decision making. In remediation projects of this magnitude, the typical process when a project team encounters uncertainty or receives unexpected results is to stop work, correspond with the EPA and wait for direction before restarting operations, which can take weeks. With the Adaptive Management Approach, the team was able to make decisions in the moment to ensure its remedy would meet EPA standards, without project shut downs, which was imperative to completing the project on time. This unique process was possible only because of the trust built between the project team and the agencies.

Approach

Phase 1: On Land

While investigating and negotiating optimal methods through which to execute the in-bay cleanup, the team began the on-land portion in 2013 after a Consent Decree was issued for Phase 1 by the EPA in 2012. Two years earlier, the EPA had issued its Record of Decision which described the cleanup parameters for both the on-land and in-bay components of the project.

Phase 1 included the remediation of the soil and groundwater of approximately 16 acres that used to house the MGP on a bluff overlooking the Kreher RV Park. To effectively treat the on-land contaminated materials, the team began by excavating 90,000 tons of soil, which equated to digging two city blocks 30 feet deep. Rather than transport the contaminated soil to a landfill, as is customary in remediation projects, the team used an on-site thermal desorption unit to heat the contaminated soils to extremely high levels, and treat the air emissions, which eliminated the hydrocarbons and cleaned the soil to enable it to be reused on site.

The next part of Phase 1 included installing underground infrastructure to collect contaminated groundwater and construct a treatment plant dedicated to treating the extracted groundwater from the site. The team installed extraction wells and six miles of piping to support the water treatment plant’s management of groundwater, including separating water from product, to produce clean water that met drinking standards for return to Lake Superior. The water treatment plant cleans 1.5 to 1.8 million gallons a month.

Most of the work related to Phase 1 was completed in 2016, and with the EPA-issued Certificate of Completion delivered in 2021, the successful remediation of the land that used to host the MGP, overlooking the lake, was complete.

In-Bay Pilot Project: From Dry Excavation to Dredging

Critical to this project was the method through which the in-bay cleanup would occur.

“Early on, the agencies were advocating for a dry excavation method in which a large portion of the bay would be sheetpiled off using a cofferdam system. The contaminated sediment would then be excavated and amended before returning treated decant water back in,” said Steve Laszewski, Senior Vice President, Foth Environment Solutions. “Our team at Foth, along with Xcel Energy, believed this method posed risks to the safety of the personnel on site and had concerns it would prove to be ineffective against the unpredictability of Lake Superior.”

After discussions and negotiations, the EPA allowed in 2014 an alternate remedy to the dry excavation technique – wet dredging – contingent on a successful pilot study. True to its reputation, a Lake Superior storm inhibited an initial wave barrier system designed by a different engineering team, using floating barges intended to create a quiescent work-in area in which to perform conventional wet dredging with barges and excavators. The initial wave barrier system was destroyed by an early September 2014 storm, sending the team back to square one. Without an effective wave barrier, the conventional wet dredging equipment would be no match for the strength of the lake’s affront.

Understanding the stakes of a successful pilot study, Foth brought together its team beginning in late 2014 to identify innovative solutions to this engineering challenge, ultimately recommending the construction of a wave attenuation system in the form of a massive rock-rubble breakwater as the optimal solution.

Between January and November of 2015, Foth designed, permitted, and constructed a 900-foot breakwater in the bay so remediation could begin in 2016, in the the already short northern Wisconsin construction season, without weather delays.

“Being the first breakwater constructed in Lake Superior in more than a decade, we understood it needed to not only provide a barrier for the effective remediation of the bay but also needed to be a long-term amenity for the City of Ashland and its residents,” said Laszewski.

Once constructed using 60,000 tons of rock procured from as far as 90 miles away, the breakwater acted as a barrier between the bay and the rest of the lake, providing stability for the barges and excavators and safety for the personnel conducting the wet dredging remedy. After successfully completing the pilot study in 2016, meeting all performance criteria, the EPA approved the method in 2017 and full dredging began in the bay.

Phase 2: In Bay

The in-bay portion of the remediation project, as well as the aforementioned pilot study, needed to meet stringent cleanup requirements due to the pristine nature of the fresh water source that is Lake Superior. A clean-up target in the range of up to 300 PPM tPAH in sediment is common for water-based remediation projects; for the Ashland Lake Superior project, the target was set at 9.5 PPM.

To achieve the remediation target, the team deployed a multi-faceted approach to the in-bay cleanup. A key challenge was to ensure that no water quality standard exceedances occurred outside of the containment area during dredging; therefore, Foth and its subcontractors installed a system of multiple layers of turbidity barriers to ensure contaminants were contained.

“The wet-dredge process included using excavators on floating barges, now protected by the breakwater, to mechanically dredge into 15 feet of water, cleaning up more than 100 years of industrial activity,” said Laszewski. “The contaminated materials ranged from tar to wood, with the dredging producing 225,000 tons of sediment and waste wood, requiring 11,500 semi-tractor trailer loads to transport to a landfill for permanent repository, after being separated, processed, and solidified as necessary.”

Once dredging was complete, core samples were collected and sent in for analysis to ensure cleanup targets were achieved. Of the hundreds of core samples analyzed, agreement was reached on achieving the dredge completion critera, leading to the successful achievement of performance standards. The team cleaned up the bay to 2.38 PPM tPAH SWAC in sediment, surpassing the 9.5 PPM target. Following completion of dredging, a residual sand/fish habitat layer was placed on the lake bed, further reducing the SWAC to just 0.03 PPM tPAH. Likewise, the stringent Lake Superior water quality standard targets for the project were maintained throughout the wet-dredge activities.

The bulk of the in-bay portion was completed in 2018, and the EPA delivered approval via its Certificate of Completion in 2020.

Results

A Waterfront for All to Enjoy

While trailing remediation continued into 2020, including installing clay liners and a soil cap with vegetation in the Phase 1 area, the waterfront was largely restored to prime condition in 2019 and returned to the City of Ashland and its residents. As of 2016, the City of Ashland began planning to develop the area into a public park and open space with a boat launch facility and fish cleaning station. The EPA deemed the cleanup “continues to protect people and the environment,” during its 2019 review and will return in 2024 for its next five-year review to ensure the remediation continues to produce successful results.

This decade-long project was complex, multi-faceted, and involved coordinating multiple agency, community, and contractor stakeholders. Safety was top-of-mind throughout the duration of the remediation. The team worked more than 480,000 person hours and performed better than the national Total Recordable Incident Rate for the General Construction and Specialty Trade Contractor sector, ensuring all personnel returned home safely to their families every day.

Foth brought the expertise of its dedicated members and its more than 25 years of experience in remediation projects to apply creativity, ingenuity, and diligence to this project. Foth’s priorities are always to exceed the expectations of its client and the agencies to which they report by ensuring quality, cost, and project milestones and deliverables are continuously met and in balance. Through being strategic, innovative, and collaborative, Foth and its partners delivered a successful project and restored an invaluable resource to the City of Ashland.

Markets: Utilities, Waterfront and Marine

Services: Coastal and Waterfront Engineering and Dredging, Design-Build / Alternative Project Delivery, Environmental and Regulatory Services, Remediation