Greetings papermakers, movers, and shakers! It was great to see everyone at TAPPICON. Now it’s time to set those insights in motion and start solving your toughest forestry challenges.

For more than 40 years, Foth has partnered with industry leaders to advance their papermaking and converting processes with a robust combination of technical expertise, industry experience, and specialized knowledge. We excel in designing and implementing systems for pulp processing, paper production, and water and waste management. We help our clients meet stringent industry standards and regulatory requirements.

Members of our team are skilled engineers with in-mill experience who are well-versed in the latest technologies and methodologies specific to papermill operations. Our project management capabilities, including planning, budgeting, and risk mitigation ensure timely and cost-effective project delivery. Additionally, our commitment to sustainability and environmental stewardship is crucial, as we understand the significant environmental considerations involved in papermill projects.

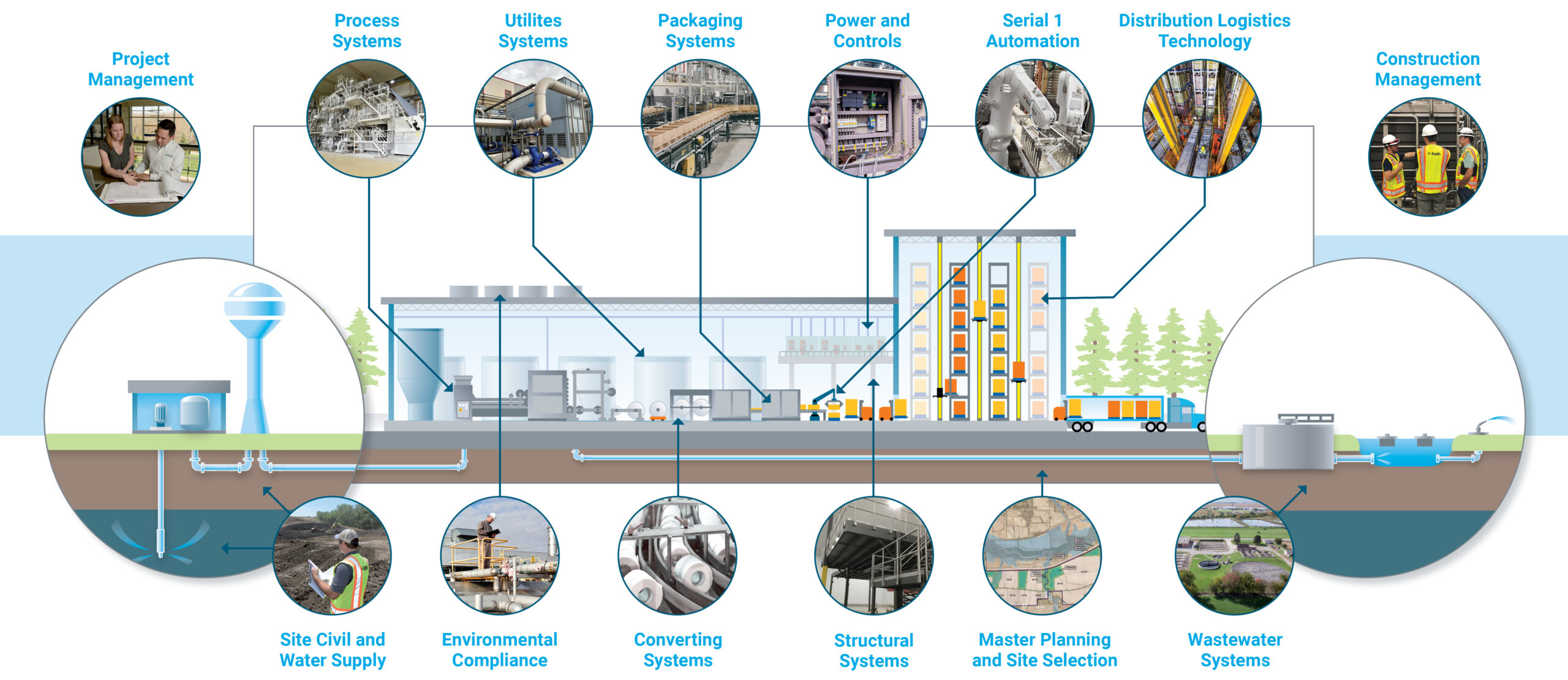

Technical Support Across Your Entire Operation

Areas of Expertise

- Woodroom

- Pulping

- Recycled operations

- Paper machine

- Paper grades

- Utilities

- Process

- Converting and finishing

- Environmental compliance and sustainability

Equipment and Supply-Chain Services

Strong relationships across the supply chain allow us to remain flexible in the marketplace to secure the best solution for your schedule and budget. Qualified vendors and relationships for pre-fabrication include:

- Custom machines

- Electrical panels

- Manifolds and skids

- Structural platforms

- Conveyors

Consumer Packaged Goods

- Towel and tissue

- Diapers and nonwovens

- Tableware, pressware, and napkins

- Corrugated packaging

- Flexible packaging

- Rigid packaging

Recent Project: Stock Prep Expansion

Goal: Expand stock preparation system, including new pulpers, transfer pumps and piping systems. Project was designed to allow for prework and a phased installation, resulting in a shorter construction schedule.

Recent Project: Tissue Machine Rebuild

Goal: Rebuild a tissue machine and ancillary equipment installation. In addition to new equipment, the scope included extensive market research for used equipment and the relocation of existing equipment from other facilities. Demolition and relocation of equipment, ducting, and piping allowed for prework and phased installation, leading to earlier setting of equipment and a shorter construction schedule.

Recent Project: Winder Safety Upgrades

Goal: Improve safety and efficiency of 1980s vintage winder, including interlocked barrier fencing. Project included removal of line shaft drive and installation of new sectionalized drives, new GuardLogix Safety PLC, safety fencing, fortress locks, and hydraulic and pneumatic system upgrades. The project also converted roll handling logic to ControlLogix platform from PLC5.

Recent Project: Dry End Roll Handling Automation

Goal: Reduce time between turnovers. Scope included replacement of existing roll handling equipment with new automated core loading system, shaft extractor, roll conveyors, and up-ender. Eliminating manual core loading onto spools resulted in reduced operator touches.

Reach Out to Learn More