Background

A major customer was producing an inconsistent product due to their existing equipment. This equipment could not meet overall throughput rates and added significant labor to their process due to mixed pallets of trays.

Approach

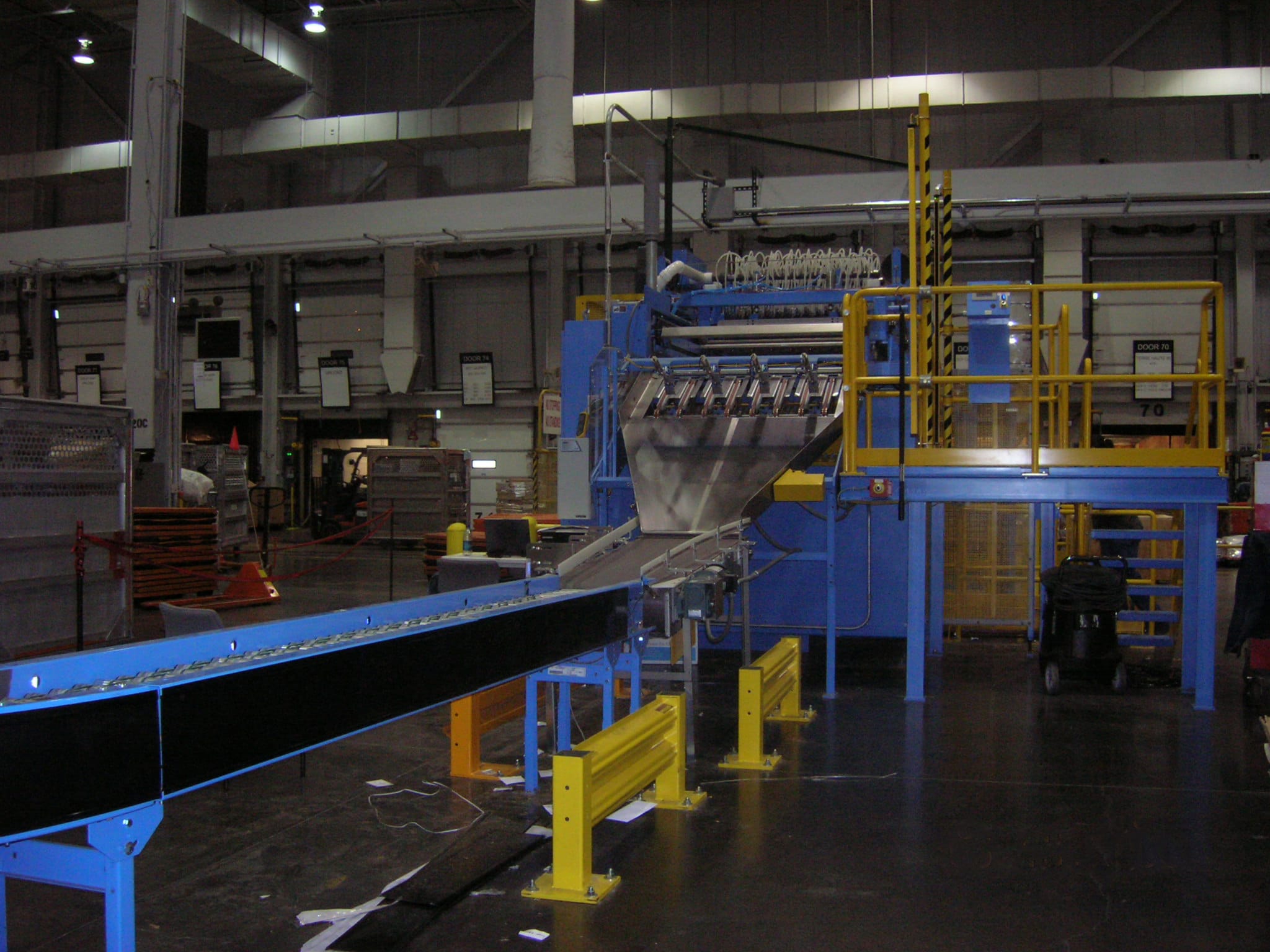

Foth was responsible for the design and manufacturing of a custom depalletizer and singulator. The project required proof of principal and modeling. Design considerations for inconsistent products, safety and automation were given.

Results

Foth was able to develop a custom machine that allowed for automated unloading of mixed tray pallets. The machine reduced safety issues and increased ergonomics for operators. This system also automated singulation of trays.

Markets: Manufacturing and Industrial Products

Services: Serial 1 Automation