Maintain Alignment Across Your Busy Project Teams

The reality of complex engineering projects is that our ability to achieve alignment among stakeholders can greatly impact the schedule, the budget and ultimately the success of a project. If there’s one make-or-break moment during the life of a project, it’s the design phase – when ambiguity, assumptions and miscommunication put alignment at risk.

Historically the design phase results in a construction package that includes two-dimensional drawings, specifications and models that need to be reviewed by decision makers – a review that usually occurs in conference rooms far from the installation site and without fabricators and operators who will ultimately build and operate the equipment in the future. But the review process is evolving with the help of new technologies that allow us to visualize and collaborate with stakeholders better than ever before.

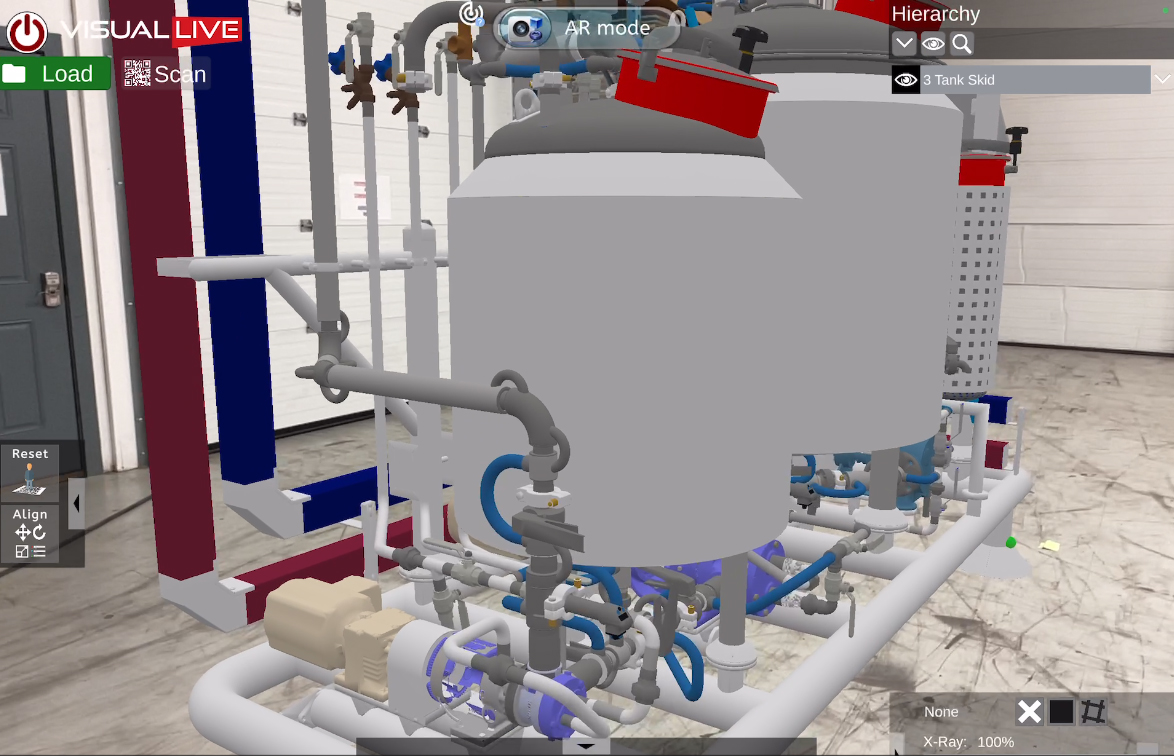

Augmented reality (AR) is one of the technologies gaining traction in the engineering industry. By overlaying digital content, such as 3D models of equipment, onto the real world, AR is changing the way we interact with our environment and revolutionizing the way we work.

Improve Communication and Remove Guesswork

Not only does AR lift the design process off the paper and into the physical world, it also allows multidisciplined teams to review, discuss and approve designs together.

While AR modeling does not eliminate traditional project documentation and drawings, it can allow stakeholders with less technical expertise to quickly see a project’s scope and impact. Unlike virtual reality (VR) models that create a standalone digital rendering, AR modeling superimposes components of the project onto an existing space and/or structure, creating a composite digital image.

Rather than requiring the use of a personal headset to experience virtual elements, our approach leverages a simpler device. By using a tablet, we create a shared experience in which multiple people can engage with a model at one time. Once teams can simultaneously see the project from their individual points of view, doors open to radically improve the efficiency of approvals by making it easier to identify potential problems and make design adjustments.

“We walked the existing site with Foth’s AR tool and ran about 10 people through the model. As a group, we were better able to visualize the new equipment in our facility and talk through operations and maintenance.”

– Jason Vandevord, Mars Wrigley

How AR Modeling Works

The first step in any project design is to understand the existing space. Our engineers and designers can use existing drawings or photos to develop a preliminary design. Or we can gain an even more detailed understanding of the existing space using our LiDAR scanning systems.

Then a 3D model is developed using industrial modeling software and loaded onto a tablet with the requisite AR software. We often travel to a site and calibrate the tablet to fit the installation area.

The final image is overlayed onto the installation area, where design teams and project managers can view it, even going inside the equipment. Stakeholders outside the team can also view the images to see their areas of interest and provide feedback to the designers. Specialized disciplines like health and safety, maintenance and repair, and machine operators can also share valuable feedback.

Beyond the Design Phase

AR modeling is well suited for complex projects that require multiple stakeholders to visualize a future state and provide feedback and approvals at all stages of the project.

While the design phase is a critical stage of any complex engineering project, the potential for error doesn’t end once construction begins. More and more, our construction management teams are turning to AR modeling as construction progresses, so that everyone can quickly align around revisions.

Foth is also investigating using AR to improve equipment maintenance by providing real-time information and assistance to technicians in the field. AR can be used to help identify components and understand how they interact with each other. This remote assistance can increase technician efficiency by connecting them to resources and experts who can guide them through maintenance or repair procedures.

Experience the Difference with AR

If you would like to learn more about AR modeling and see how it can be applied to your project, contact us. We are happy to talk with you about the nuts and bolts of the technology, discuss your complex project, and see whether AR modeling is a fit for you.

In the meantime, watch a video that demonstrates how we use AR technology to achieve alignment with project teams.

Markets: Consumer Products, Food and Beverage, Manufacturing and Industrial Products, Pulp and Paper

Services: Automation and Custom Machinery, Design-Build / Alternative Project Delivery, Engineering for Product Manufacturing