Serial 1 Automation Accelerates the Pace of Growth and Profit

In the manufacturing industry, where margins are tight, and competition is fierce, small advantages can make a big difference. Whether the goal is to reduce costs, meet sustainability objectives, or seize an opportunity to carve out an entirely new market niche, companies often arrive at a point where changes to existing equipment and/or processes are required to move the needle. In these instances, many will look to automation to solve their challenges.

But what happens when there is no off-the-shelf piece of equipment that does the trick? Companies are forced to either turn to an original equipment manufacturer (OEM) and risk investing in a solution that doesn’t hold up or watch that once-promising competitive advantage slip away.

Special circumstances call for specialized expertise. To solve for the challenges created by customization, Foth has established a multi-phased approach: the Serial 1 Automation process. Through it, we develop purpose-built equipment that helps manufacturers get products to market more quickly and reliably and closes gaps in labor-scarce industries.

Developing a Customized Automated Solution to Solve your Unique Challenge

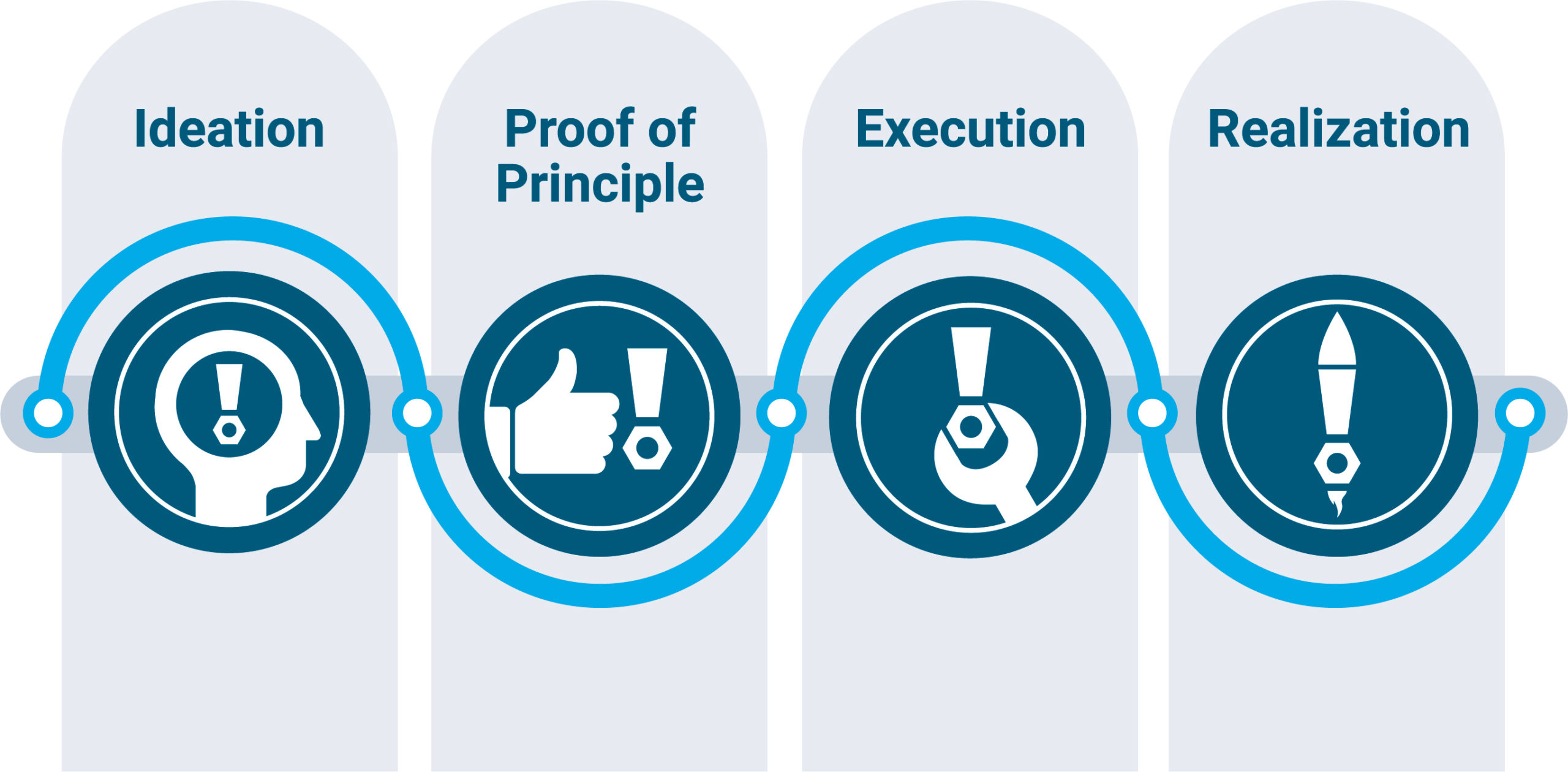

The Serial 1 process brings a rigor, quality, and systems thinking to every new challenge. Through disciplined application of its four phases, it helps companies improve operations, safety, and efficiency with fit-for-purpose machines and systems that perform unique, automated production and processing functions.

Because they are designed specifically to each manufacturer’s specifications, these automated solutions address both concerns and opportunities that are unique to the individual manufacturer, whether they’re in consumer products, construction, or industrial manufacturing. Typical challenges deal with complex ergonomic requirements, environmental impact mitigation, supply chain management, product obsolescence, manufacturing process performance, and the desire to change the game by bringing first-of-a-kind products to market.

The Serial 1 process pulls together skilled and knowledgeable mechanical design engineers, controls engineers, and project managers who work together from concept to final acceptance. The process draws on Foth’s vast experience in diverse markets and industries to produce innovative solutions for manufacturers in disparate industries. Regardless of the final output, the benefit of Serial 1 is that it gives manufacturers a custom solution that addresses their specific operations, product, and technology needs.

Every plant, manufacturing process, and assembly line is its own puzzle. When a manufacturer wants to automate a portion of that puzzle, it needs a piece that will fit within existing systems, not something that will require extensive retrofitting.

The goal of the Serial 1 process is to create that perfectly fitting puzzle piece, either as an addition to or replacement of others in the system. A piece that removes redundancies, creates efficiencies or improves flexibility.

Serial 1 Automation Carves a Path to Success

Each of the four phases of the Serial 1 process serves as a precursor to the next. Too often customization projects follow an ad hoc process and continue to implementation without pausing for viability checks. There are two unique aspects to Foth’s process that solve this conundrum:

- Advancing to the next phase is not imminent. The decision to continue developing a new component, system or process rests solely with the company and their confidence in the solution.

- The Proof of Principle phase is intended to test the riskiest and trickiest aspects of a concept to prove or disprove viability. This phase takes on many shapes and sizes, from modeling to full prototypes, but one aspect is the same every time: only when a concept has been de-risked does the process continue to the remaining phases.

1. Ideation – Concept Development & Feasibility

- Phase I captures divergent solutions and roughly qualifies them for economics, reward versus technical risk, and viability.

2. Proof of Principle & Preliminary Engineering

- Phase II reduces the technical risks identified in Phase I by stress testing the most challenging parts of the solution to prove what is viable.

- The Proof of Principle phase evaluates math, physics, technology, ergonomics, economics, time, and legal/IP to deliver the viable operating window for the final design.

- Low-cost, fast-turn, and easily modified models help reduce risk and add value.

- This is where we discover whether our early ideas are effective. If not, we look for alternative ideas, modifications, or combinations of ideas that are.

3. Execution – Engineering & Manufacturing

- Phase III involves the design, engineering, and manufacture of the equipment.

- Evaluations are made for functionality, performance, ergonomics, safety, manufacturability, changeovers, and maintenance.

4. Realization – Installation & Startup

- Phase IV includes installation of the final product at the site, overseen by Foth’s field support team.

- Foth remains on-site to ensure the solution is working as expected.

By following the Serial 1 process, which includes a viable proof of principle, the final solution addresses the manufacturer’s specific requirements, outperforming most ready-made automation solutions – assuming such a thing even exists. Having a purpose-built piece of equipment that performs exactly the way the company needs it to, and owning the associated intellectual property, results in a worthwhile investment. These benefits can only be realized as the results of a rigorous process that delivers assurance along the way.

Competitive Advantage

Foth has many examples of how this process has worked to solve some of the toughest engineering challenges in manufacturing. We have hard-earned expertise, demonstrated through a strong portfolio of successful projects. Our clients benefit from improved chances of success, lowered risk, greater efficiencies, enhanced ability to anticipate challenges and overcome obstacles, reduced end-to-end project timelines, and the opportunity to own the resulting intellectual property.

We excel at delivering first-of-a-kind automation solutions to the consumer goods marketplace. That’s our competitive advantage. Let’s create yours.

Contact us to discuss your toughest challenges and how Serial 1 Automation can bring unrivaled benefits to your next project.

Markets: Consumer Products, Food and Beverage, Manufacturing and Industrial Products, Pulp and Paper

Services: Automation and Custom Machinery, Design-Build / Alternative Project Delivery, Engineering for Product Manufacturing, Serial 1 Automation, Strategic Consulting and Planning