Rethinking Machinery for Competitive Manufacturing

Margins are tightening. Labor is scarce. Capital is shifting. For manufacturers in food and beverage, paper, industrial, and consumer products, the pressure to do more with less has never been greater.

Traditional automation and off-the-shelf equipment can take you far, but what happens when your process is unique, your quality requirements exceed what the market offers, or your opportunity for differentiation lies in how you make your product, not just what you make?

That’s when custom automation stops being a last resort and starts becoming a strategic advantage.

The Challenge Facing Today’s Manufacturers

Leaders across the industry are grappling with a familiar set of pressures:

- Margin compression from rising input costs and retailer power

- Labor shortages and cost increases are here to stay, forcing plants to run leaner

- Capital expenditure shifts toward technologies that promise flexibility, efficiency, and long-term returns

- Space constraints that force footprints to be optimized, often by consolidating multiple processes into one

- Quality and compliance demands that leave little room for process variation or human error

Yet OEM-standard machines are designed for broad applicability, not your specific product flow. They rarely optimize for precision, integration, resource intensity, or space utilization in the way your operation might require.

The wrong machine doesn’t just limit throughput, it can quietly erode margins and stall innovation.

Custom vs. Off-The-Shelf

Off-the-shelf solutions are typically faster to deploy and come with lower upfront costs. However, they are designed for general use, which can lead to inefficiencies, workarounds, and limited flexibility. Intellectual property generated through use often contributes to vendor development, reducing long-term control and accelerating obsolescence. These systems are also widely accessible, offering little competitive differentiation.

Custom automation, by contrast, is engineered to fit your specific process. While it requires more time and investment, it delivers tailored performance, scalability, and integration. Businesses retain full ownership of their intellectual property, protecting innovation and enabling long-term strategic advantage. Custom solutions are built with future growth in mind and offer unique capabilities that competitors cannot easily replicate.

What’s at Stake for Market Leaders

If your production process relies on equipment not fully aligned with your product, you risk:

- Hidden inefficiencies: Manual workarounds, wasted labor, and unplanned downtime quietly erode margins

- Missed growth opportunities: Off-the-shelf solutions often limit scalable capacity for new SKUs, co-packing, or private-label contracts

- Increased costs: Retrofitting, frequent maintenance, lower yields, and higher scrap rates are common with generic equipment

- Competitive disadvantage: Competitors leveraging custom solutions can differentiate on quality, flexibility, and speed to market

- IP risks: Relying on OEMs may limit your ability to protect process innovation and shorten the lifecycle of your technology

Executives who view machinery as a fixed constraint risk losing ground to those who see it as a lever for competitive advantage. Custom automation isn’t just about solving today’s challenges, it’s about enabling tomorrow’s growth.

True ROI in automation comes not from machines alone, but from aligning engineering design with business outcomes.

The Business Case for Custom Machinery

Before investing in custom machinery and automation, leaders should consider the following:

- Optimization Factors: What are the root causes of the process challenge that automation can address?

- Process Fit: Does standard equipment meet 80% of needs, or is the gap too wide? Too costly? How does it affect process risk?

- ROI Timeline: Can improvements in throughput, scrap reduction, or labor efficiency justify investment?

- Scalability: Will the solution adapt to new product formats or volume growth?

- Integration: How will custom machinery connect to upstream/downstream processes, WMS/ERP, or packaging lines?

- IP Ownership: Will the design strategy remain proprietary to protect long-term advantage?

- Risk Profile: What’s the implementation risk versus continuing with workarounds or manual intervention in legacy systems?

Real World Results

The Serial 1 Automation team has delivered impactful solutions for manufacturers seeking performance beyond standard equipment. For a major food producer, Foth helped launch a custom flexible gallon dressing package to replace rigid plastic containers. With limited off-the-shelf options and a tight timeline, the new system increased output from 3 to 60 pouches per minute, reduced material use, and earned a DuPont Packaging Innovation Award.

In another case, a Wisconsin-based consumer goods company modernized a decades-old filler line. Foth’s custom solution improved safety, reduced defects tenfold, increased production speed by 20 percent, and elevated packaging quality to record levels.

Why Foth?

What sets Foth apart is not just design expertise, but end-to-end capabilities. We help manufacturers evaluate standard options first, then build a business case for custom solutions when differentiation matters.

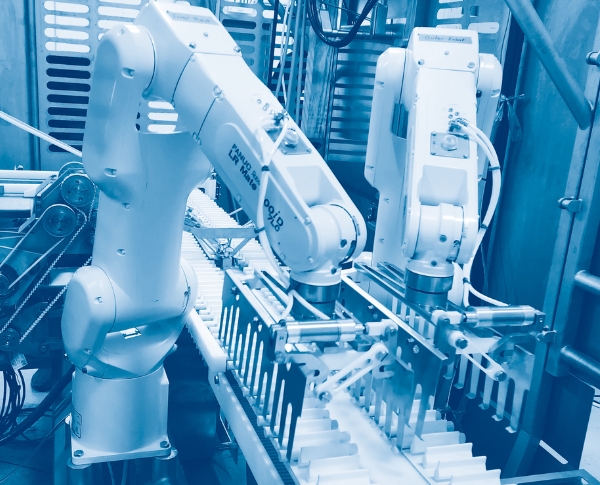

The Serial 1 Automation team includes over 40 engineers, designers, and project managers with deep experience in high volume environments. We offer mechanical, electrical, controls, and integration expertise under one roof, backed by Foth’s broader infrastructure capabilities. Our brand agnostic, engineering first approach ensures solutions are built around your needs, not a product catalog.

The Path Forward

The decision to pursue custom equipment should be a disciplined, data-driven one, not an emotional leap. With the right partner, you gain more than a machine; you gain a long-term edge.

Foth’s Serial1 Automation team helps manufacturers:

- Validate business cases before investing.

- Design, build, and integrate custom solutions when warranted.

- Protect intellectual property and innovation pathways.

- Deliver projects that work not just on paper, but in the realities of your plant floor.

Ready to explore whether custom automation could unlock capacity, efficiency, or competitive edge in your operation?

Markets: Consumer Products, Food and Beverage, Manufacturing and Industrial Products, Pulp and Paper

Services: Engineering for Product Manufacturing, Serial 1 Automation