Background

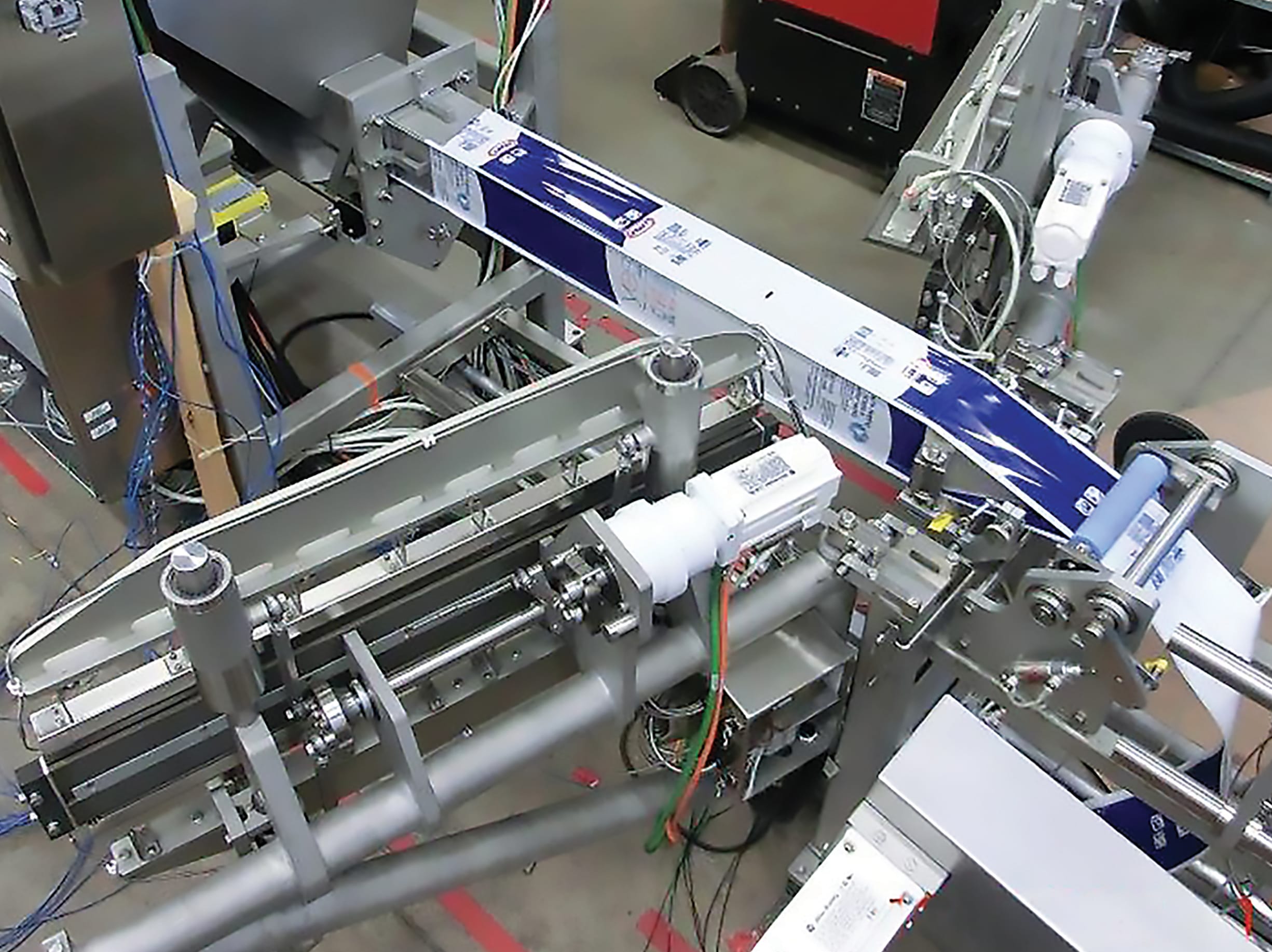

After concepting an innovative and environmentally friendly flexible gallon dressing package, a large food manufacturer turned to Foth to develop the custom equipment that would produce and fill their new package design with salad dressing. The first of its kind, the package would replace the large one gallon rigid plastic container used by their current food service customers. We were tasked with inventing and manufacturing the necessary equipment as well as developing the overall line design and integration process in less than a year to ensure our client was first to market.

Approach

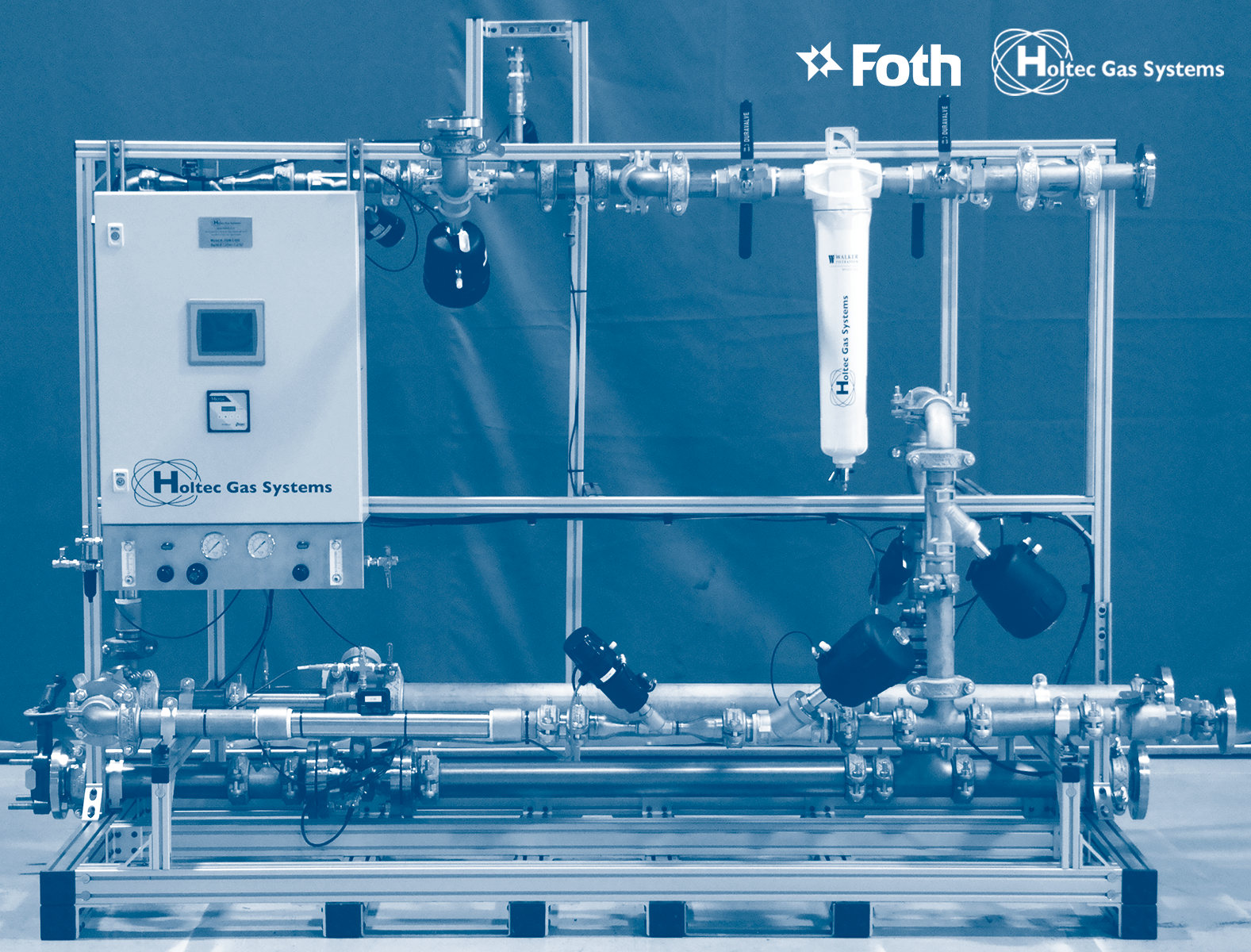

Working closely with the client and film suppliers, Foth was responsible for the concept development and proof of principle modeling that led to an acceptable custom equipment solution. Upon client approval, we completed the final detailed design and guided the manufacturing, assembly and testing of the equipment. Provisions included a performance guarantee and warranty for the provided equipment. The client was given proprietary ownership of all drawings and information.

Results

Foth met the aggressive timeline and delivered a product to help food service operators manage costs and improve back-of-house efficiencies, including an improved dressing yield of up to 99 percent. Compared to the production of the rigid gallon jug, the new packaging was made with less energy, less plastic and fewer CO2 emissions from transportation.

Along with our client, Foth received the prestigious DuPont Award for Packaging Innovation in honor of our successful development of custom equipment used to create an innovative and environmentally friendly package.

Markets: Food and Beverage

Services: Serial 1 Automation