Background

Carbon Dioxide (CO2) usage in breweries, wineries and distilleries ranges from product carbonation to elimination of oxygen in the production and packaging operations. The production of CO2 from fermentation supplies the majority of CO2 used at many breweries. However, most breweries use more CO2 than what is collected and purchased CO2 is often required. In fact, some larger facilities spend over $1 million on CO2 annually, making it one of the more expensive operating costs.

While the price of CO2 has always been a factor, there have been many CO2 supply chain issues recently including the truck driver shortage and shutdown of supply sources. This makes it difficult for breweries to procure the needed supply.

Due to the rising costs of CO2 and supply chain issues experienced since COVID-19, other gases may be beneficial in relieving the supply chain issues and saving overall operation costs.

Approach

Nitrogen (N2) is a commonly used gas in the brewing industry that does not react with beer. The production of gaseous N2 on site can be economically generated, making N2 systems significantly less expensive compared to CO2 collection equipment. The operating costs to self-generate are competitive to operating a CO2 collection system. The cost to generate an equivalent ton of N2 is $10-$20 per ton compared to purchased CO2 at $50 to $200+ per ton. Supply chain issues have caused additional surcharges that can exceed $1,000 per ton!

Using self-generated N2 to offset purchased CO2 is an opportunity to save money, reduce greenhouse gas footprint, alleviate supply chain issues associated with purchased CO2.

Results

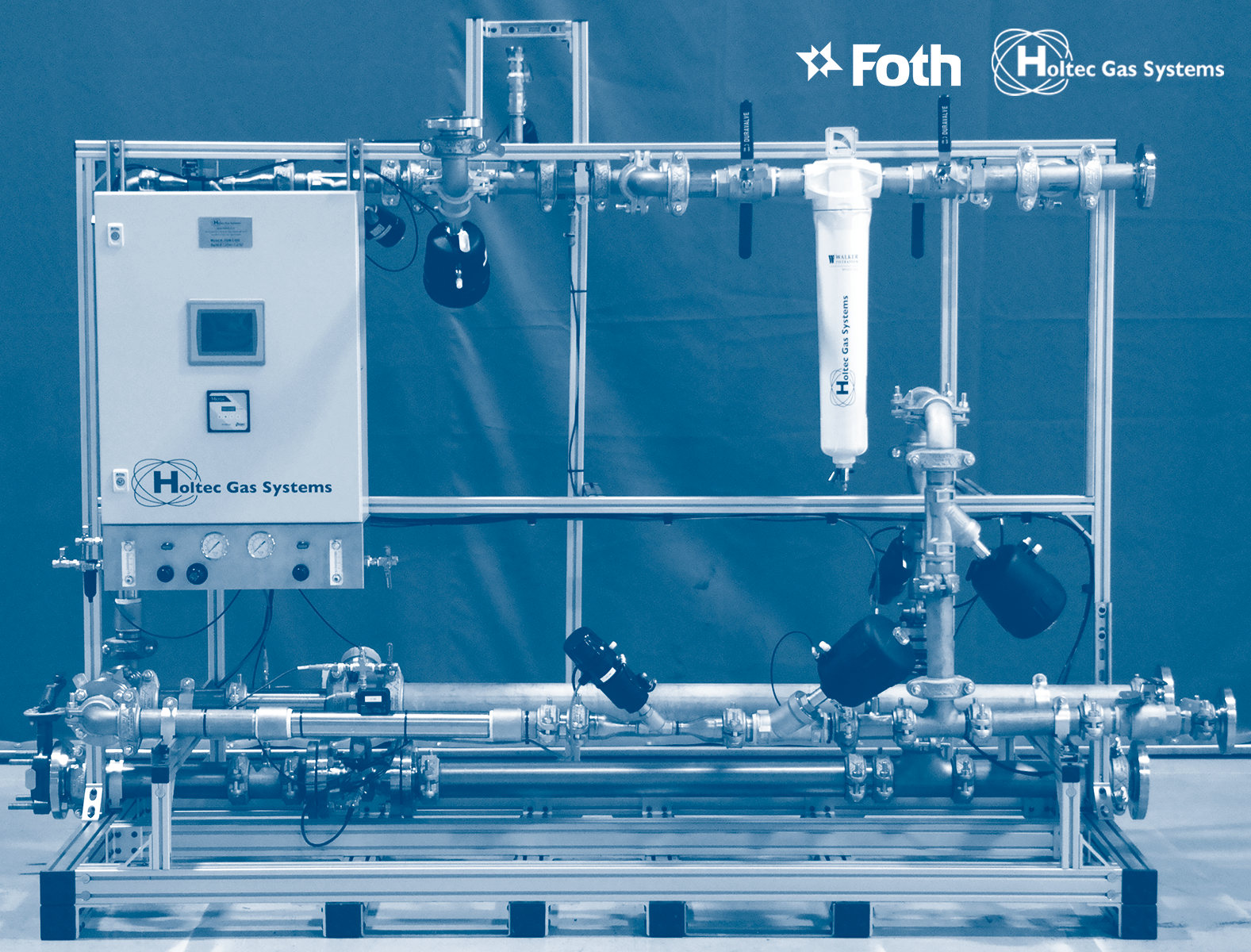

We have developed an N2/CO2 mixing system design that allows for high volume, high accuracy gas blending for use in the packaging operation. With carbonated beverages, it is important to have enough partial pressure of CO2 in the filler bowl to maintain carbonation levels in the package. Combining this proprietary mixing technology with an N2 generating system can achieve a 50% reduction in packaging CO2 consumption.

We have also developed mixing technology options to use at the packaging line level for customers with complex packaging requirements.

This mixing technology will reduce brewery costs and achieve an overall CO2 footprint reduction while minimizing risk of supply chain issues.

Markets: Food and Beverage

Services: Engineering for Product Manufacturing, Serial 1 Automation