Background

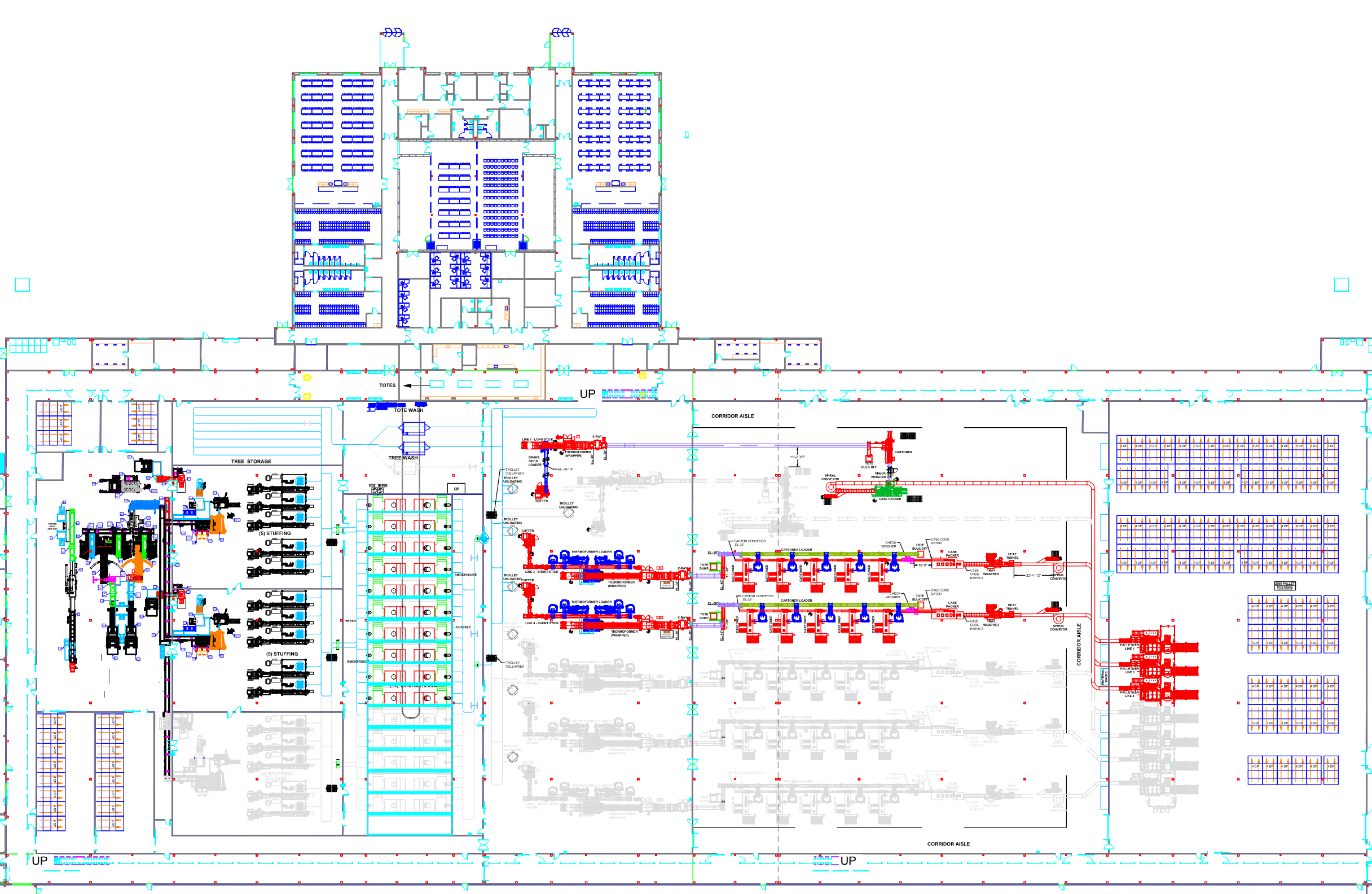

Our client was looking for a solution for a bottleneck at the dry end of the paper machine that required reducing the processing time of the reels of paper between turnovers. We worked with our client and the OEM to develop a replacement system that included a new automated core loading system, shaft extractor, roll conveyors and an up-ender. This automated system eliminated the need to manually load cores onto the reel spools and reduced the number of operator touches.

Approach

Having accurate field measurements of existing equipment was accomplished during a routine planned outage, using 3D laser scanning. This enabled the OEM to make design changes to the automated components prior to fabrication. We also used the scan data to do the structural steel design changes that were necessary for extending travel on the Overhead Roll Crane. We also provided the controls programing for the new Roll Handling system, including safety programing and validation.

Results

The use of the 3D scanning data allowed accurate design and fabrication of the automated system, saving installation time and rework. Our technical knowledge of the unit operations of the dry end allowed the safety programing to be completed in advance and validation went smoothly. A collaborative approach with engineering, construction, OEM and operations lead to a successful installation and start-up.

Markets: Pulp and Paper

Services: Engineering for Product Manufacturing