Background

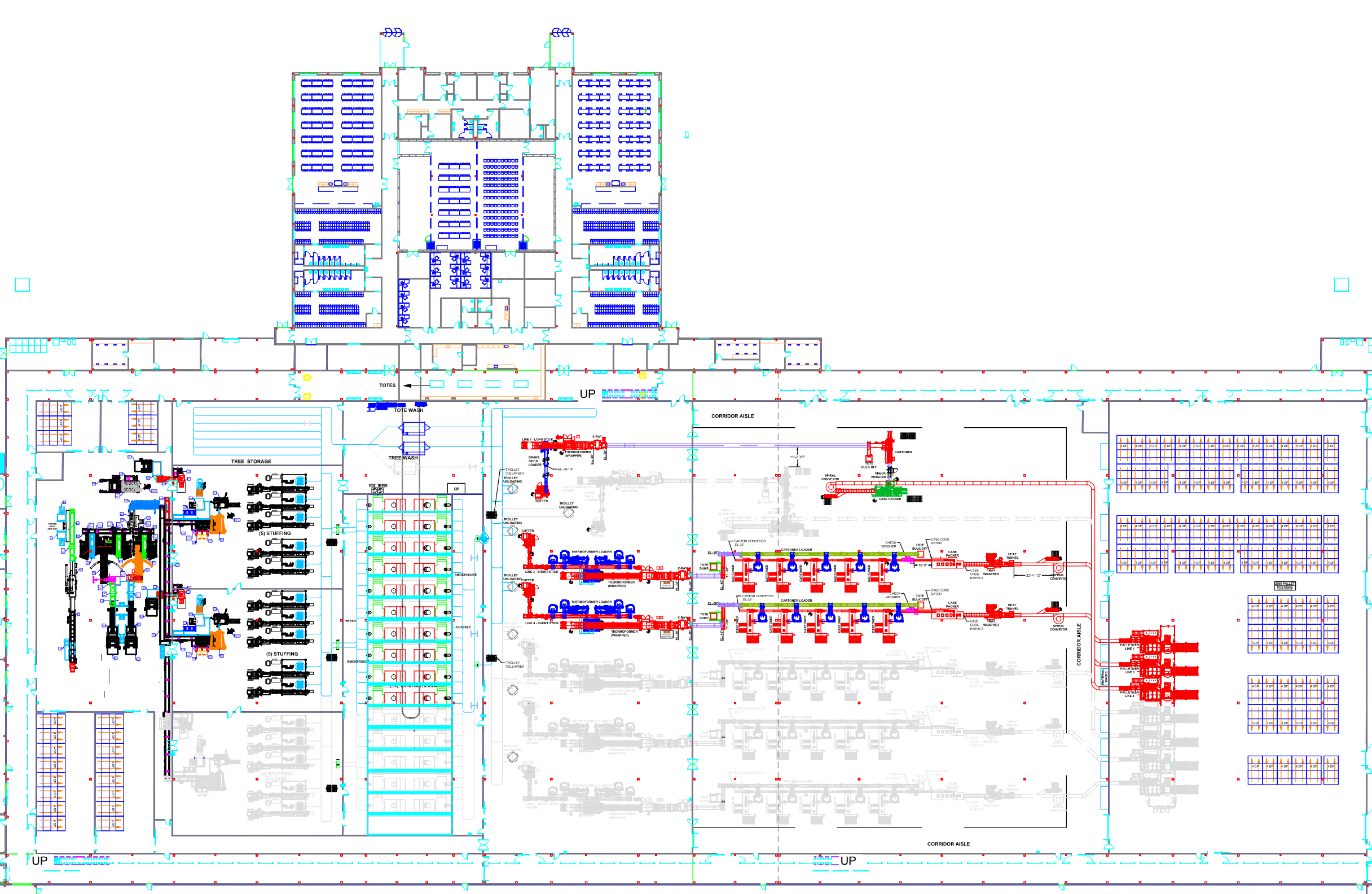

Our client funded an initiative to improve the guarding on the dry end of eight paper machines. Working with the site safety leader, we performed task based risk assessments to establish safety zones and running line standards. Based on the assessments, we were able to design guarding packages that were integrated into the existing OEM equipment. These designs met AMEC Entry and Cat-3/PLd ratings. In addition, new auto feed tail threading equipment was added to eliminate rope threading.

Approach

Using 3D scanning we were able to capture accurate “as built” conditions for the dry ends of the paper machines. Since the goal was to re-apply a standard OEM air threading system, the model allowed us determine the modifications to the design packages on each installation. It also allowed reapplication of the equipment controls integration for the safety zones.

Results

Construction and installation went smoothly. Subsequent installation and outages were planned and executed in 1 to 2 days less time. The 3D scanning was embraced by all parties. The ability to reapply designs packages process, mechanical and electrical was a significant cost savings.

Markets: Pulp and Paper

Services: Engineering for Product Manufacturing